Dry core series reactor

Environmental usage conditions:

a. The altitude of the area of use shall not exceed 1000m.

b. The ambient temperature in the area of use: -40~+45 ℃.

c. The place of use should be free from severe mechanical vibration, harmful gases and vapors, and conductive or explosive dust.

4.2 Other usage conditions:

Before the capacitor is put into operation, the remaining voltage between its terminals should not exceed 10% of the rated voltage. When capacitors involve high relative humidity, rapid mold growth, corrosive atmosphere, pollution, and altitude exceeding 1000m

Category:

Keywords:

Dry core series reactor

Details

1. Product use

Dry type iron core series reactor is suitable for 6, 10, 20, 35kV power system, and is used to suppress the voltage waveform distortion of power grid, so as to improve the quality of power grid and ensure the safe operation of power system; The harmonic current flowing through the capacitor bank is suppressed and the inrush current is limited so as to protect the capacitor for safe and reliable operation.

2, product function

The reactive power compensation device is formed in series with shunt capacitors. Its functions are as follows:

1. Limit or even eliminate the amplifying effect of power capacitor banks on harmonics in the system without series reactor.

2. Reduce the closing inrush current and inrush current frequency of capacitor banks, easy to choose circuit equipment and protect capacitors.

3. Reduce the harmonic voltage on the bus to improve the power supply quality.

4. Limit the flow of current higher than the harmonic into the capacitor bank, restrain the high harmonic and protect the capacitor.

5. Reduce the discharge current from the healthy capacitor bank to the faulty capacitor bank to protect the capacitor.

6. Reduce the inrush current multiple and frequency when the capacitor bank circuit breaker breaks the arc, so as to eliminate the arc at the break and reduce the operating overvoltage amplitude.

3. Operating environment conditions

1. Use place: indoor, the surrounding environment should have good ventilation conditions, such as installed in the cabinet should be equipped with ventilation equipment.

2. The environment temperature: - 25 ~ + 45 ℃.

3. Relative humidity: monthly average is not more than 90%, daily average is not more than 95%.

4. Altitude: No more than 1000m (more than 1000m when ordering).

5. Earthquake resistance: can withstand the intensity of 8 degrees earthquake.

6. The installation and operation area shall be free from harmful gas, steam, conductivity or explosive dust.

(If there is any special request, please indicate it when ordering.)

4. Implement standards

1. GB/T1094.6-2011 "Power transformer Part 6: reactor"

2. JB5346-2014 "Series reactor for High voltage shunt capacitors"

3. IEC280-1987 Reactor Standard

4. DL462-92 "Ordering Technical Conditions of Series reactors for High voltage Shunt capacitors"

5. Product structure

1. The reactor core is made of high quality silicon steel sheet, and the core column is divided into uniform segments through multiple air gaps. The air gap is isolated by epoxy cloth plate, so as to ensure that the air gap does not change under the long-term operation of the reactor.

2. The end face of the reactor core adopts high quality silicon steel sheet rubber, so that the silicon steel sheet is firmly combined together, greatly reducing the noise during operation, and has a better anti-corrosion ability.

3. The coil is of epoxy pouring type, and epoxy glass mesh cloth is set inside and outside the coil to strengthen it. The H-grade epoxy pouring system is used for pouring under vacuum condition.

4. The epoxy pouring coil does not absorb water, and the local discharge power is low. It can operate safely under harsh environmental conditions.

5. The upper and lower end of the coil adopts epoxy pad and silicone rubber shockproof pad, which effectively reduces the vibration of the coil during operation

6, dry type iron core reactor than the traditional oil-immersed reactor, hollow reactor volume is smaller, with light weight, small space, simple structure, convenient installation and so on.

6. Technical specifications

1. Can be used for 6kV, 10kV, 20kV, 35kV power system.

2. The types of reactance are 1%, 4.5%, 5%, 6%, 7%, 12%, 13%, etc.

3. Insulation class: F or H. During normal operation, the temperature rise of the dry core reactor is not more than 85K, and the temperature rise of the coil is not more than 95K.

4. Dry core reactor can run for a long time at 1.35 times rated current.

5. The noise of dry core reactor is not greater than the value specified by the national standard.

6. The voltage level of dry core reactor conforms to the provisions of JB5346-2014 Series Reactor for High voltage shunt capacitors.

7. Matching capacitor capacity 1kvar-20000kvar.

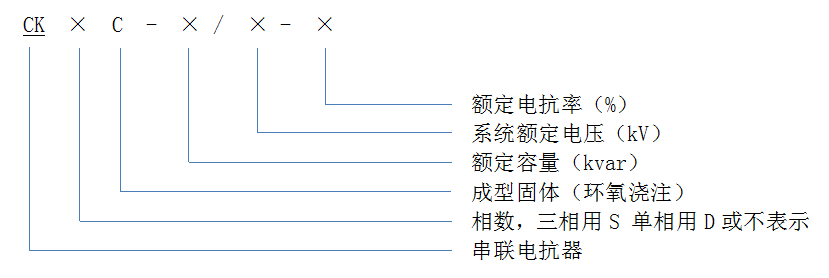

7. Model description

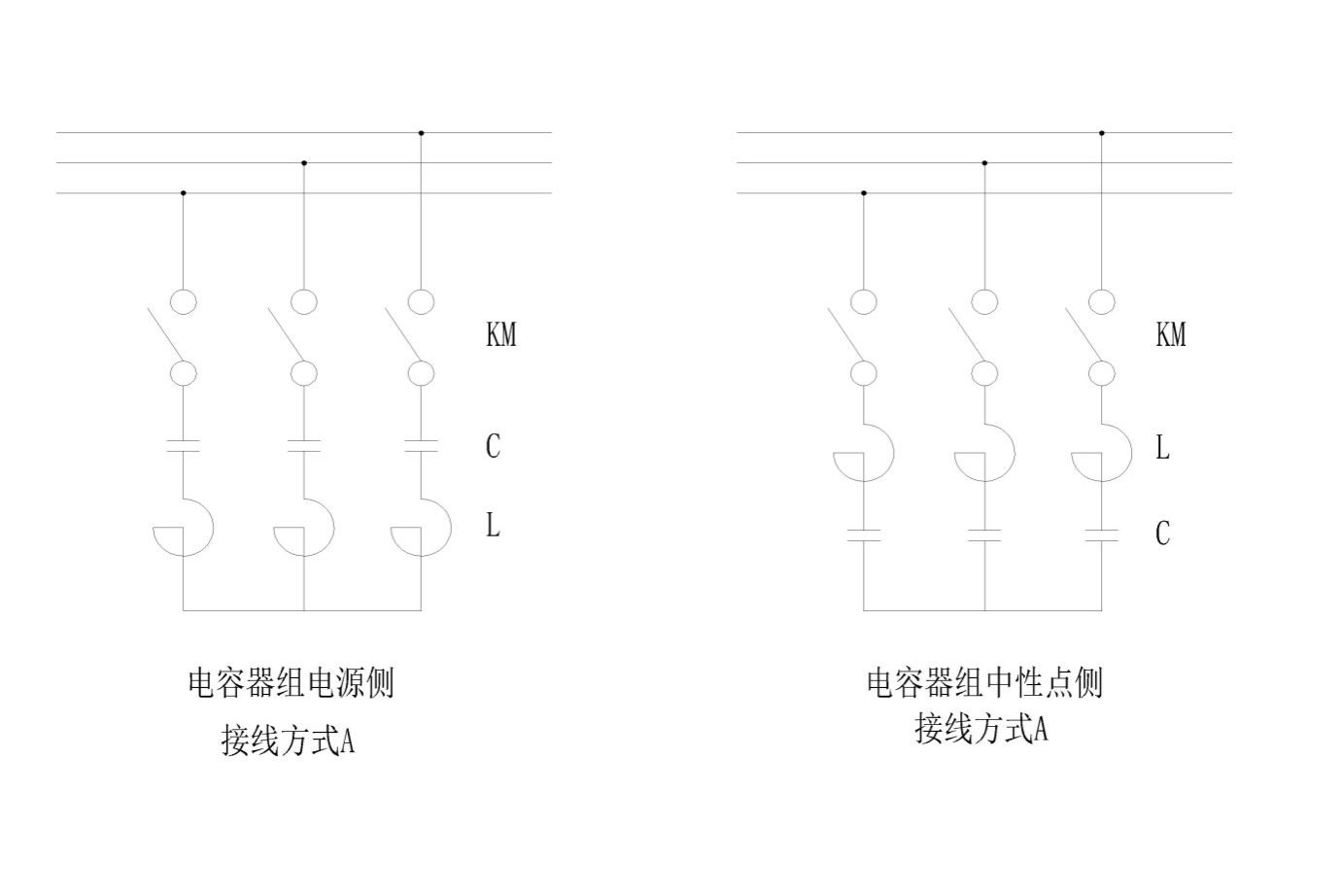

8. Wiring mode

The company's product quality assurance, reliable use, CKSK type dry hollow series reactor and capacitor device good compatibility, price concessions, good service. We warmly welcome users from inside and outside the province to contact us.

Online consultation

Any questions can give us a message, we have professional staff to reply to you, please be sure to fill in the correct contact information!

Recommended products